Machining and cutting to size

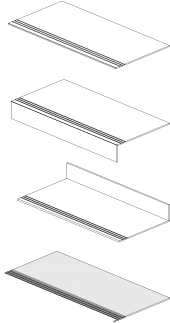

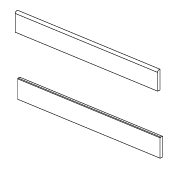

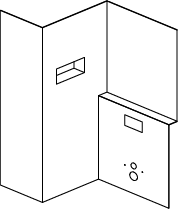

From the ABL Cutting Studio, you can obtain made-to-order mitred corner tiles, stair tiles with grooved edges, nosed stair tiles, tiles with high-vis-coloured front edge, and skirting board tiles for your project. The porcellanato tiles in our range are available in the size required.

The Cutting Studio is at your disposal if you want elaborated special versions of our ceramic products for your project. You can have all of our porcellanato tiles cut to the size of your choice and order made-to-measure items of the same product for the corners and stairs. Work site installation is easy, for the products are delivered finished and ready for installation.

A novelty in our cutting studio is a mitre cutting machine that cuts and grinds miters on tiles, stone slabs and large ceramic tiles. With this, we ensure a finished impression on the products. Please contact us, we're happy to help with your next project!

You can order mitre cut, stair tiles grooved on the edges, custom bullnose stair tiles, baseboard tiles cut from our tiles for your project. Ask us about the possibilities, we'll find a way to make it.

|

|

|

|

|

|

|

|

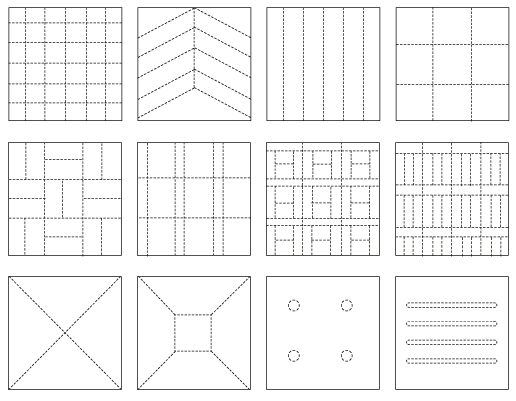

Do you need your tiles or ceramic surfaces in particular size or shape? Let us help! ABL Leikkaamo delivers all our stoneware porcellanato tiles and ceramic tiles in the shape and size you wish.

If you can't find a mosaic tile of the shape you want, or you want to use a tile cut from a larger size, we can deliver the products you want precisely cut to size.

All cutting operations performed at the Cutting Studio are inspected before delivery. All apertures cut are checked in accordance with the aperture data/dimensional data of the products to be recessed.

• Product length/width dimensions after the cutting +1/-2mm

• Taper over 600mm: +/- 1mm

• Normal bevel width: 2-3mm (when done by hand, the bevel angle may vary slightly)

• Accuracy of aperture works in case of top-mounted products: +3/-0mm

• Accuracy of aperture works in case of bottom-mounted products: +/-2mm

• Accuracy of lip works in case of products installed onto a lip (length/width): +/-1mm

• Accuracy of lip works in case of products installed onto a lip (depth): +/-0.35mm

• Accuracy of other aperture machining: +/-2mm