ABL Sockel System® facade tiles

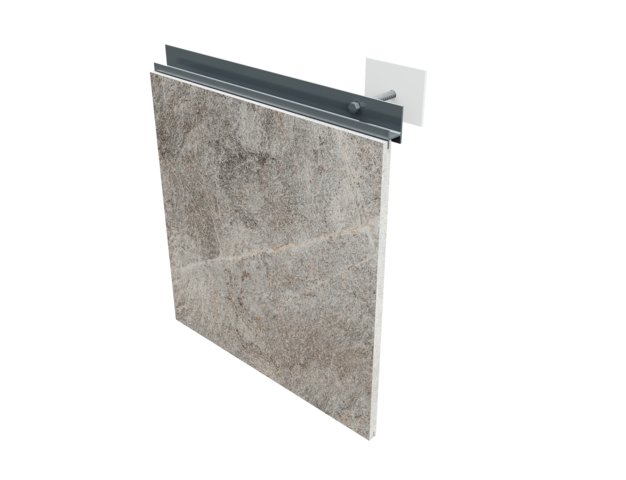

Cladding of building plinths or façades with ceramic façade tiles. ABL Sockel System® is a rear-ventilated, easy-to-install solution.

Are you planning a façade renovation or a long-lasting and impressive façade solution for a new building? ABL Sockel System® brings a wide range of technically high-quality façade tiles impressive by appearance and usability to façade construction. The scale of colours and sizes enables individual and attractive façade solutions.

The ABL Sockel System® ceramic façade tiles are 20mm thick dry-pressed tiles with pre-made grooves at the fastening points. In terms of technical characteristics, they constitute an excellent choice for plinth cladding and the volatile weather conditions typical for Finland. They have been fired at high temperatures to an extent ensuring frost resistance, non-combustibility, and high strength values. The façade tile surface is not susceptible to limescale, which means that the plinth will retain its appearance for many decades.

Design freedom. The wide choice of different sizes and colours offers the designers plenty of options and freedom. Plinth tiles are available in concrete, wood, granite, terrazzo, and stone patterns. In addition, façade tiles can be tailored to the sites.

Retention of material colour and shape. The façade tiles used for plinth cladding are dry-pressed tiles. The high-temperature firing during the manufacturing process ensures that the plinth tiles are tight, frost-resistant, non-combustible, and have high strength values. The façade tile surface is not susceptible to limescale, which means that the plinth will retain its appearance for decades.

The technical characteristics of ABL Sockel System® ceramic façade tiles are perfectly suited to Finland’s changing weather conditions. The rear-ventilated system protects and allows the structures to breathe. The air cushion created between the wall structures and façade surface prevents energy loss in cold weather and keeps the indoor climate pleasant in the summer heat.

Cost savings over the life cycle. As a long-lived and virtually carefree solution, a ceramic façade system will pay off through energy savings related to heating and air conditioning costs.

Safety first. Ceramic façade systems are characterised by first-rate fire safety. In case of a fire at the real estate, the products will not ignite or emit hazardous chemicals.

The plinth tiles are accurately cut to the size necessary for your project. Project-specific customizations of tones and sizes are possible.

20mm thick façade tiles are available in the following size classes: 30x60cm / 60x60cm / 40x80cm / 60x90cm / 45x90cm/ 40x120cm, and 60x120cm. Bevelled tiles are also available in all sizes, and project-specific customizations are naturally possible.

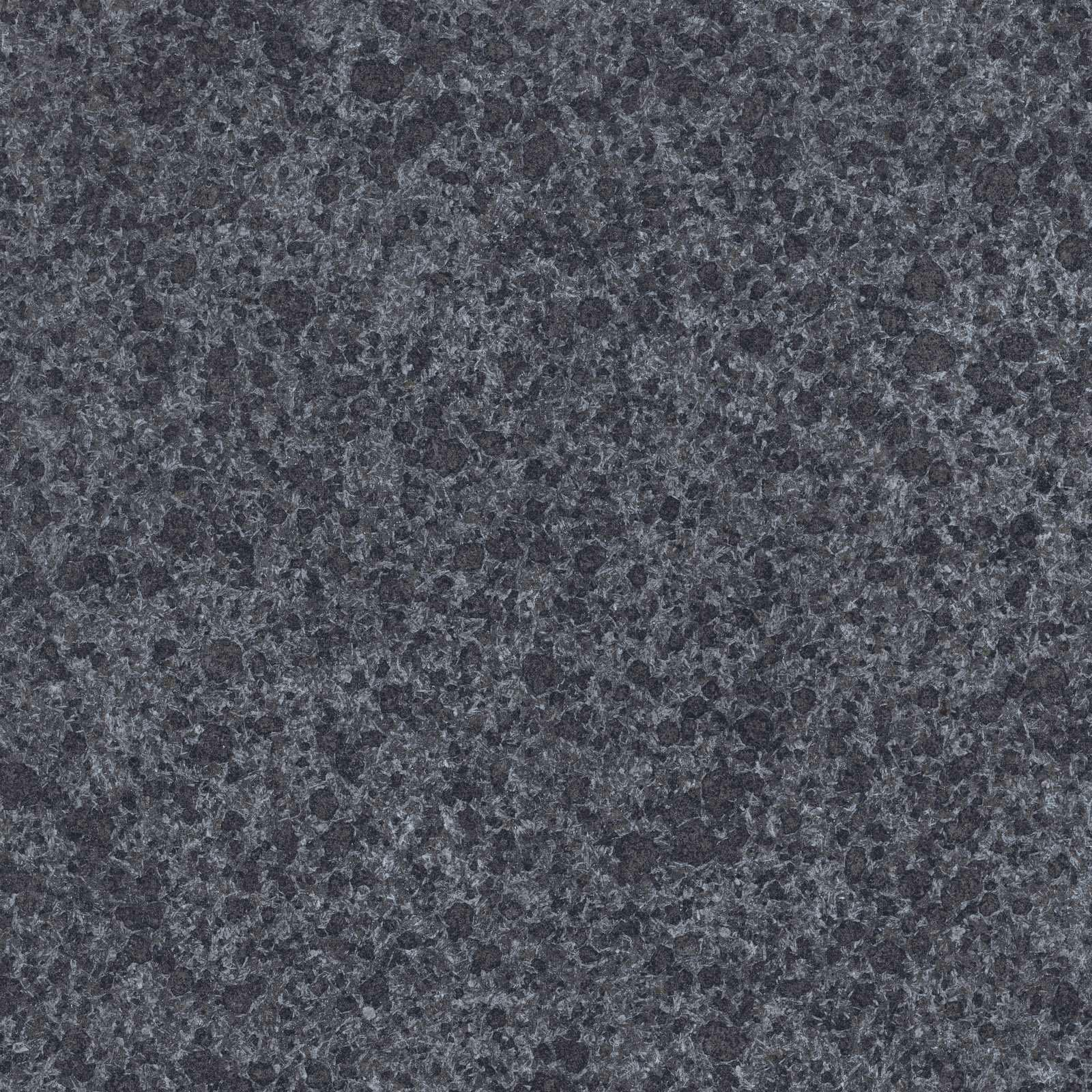

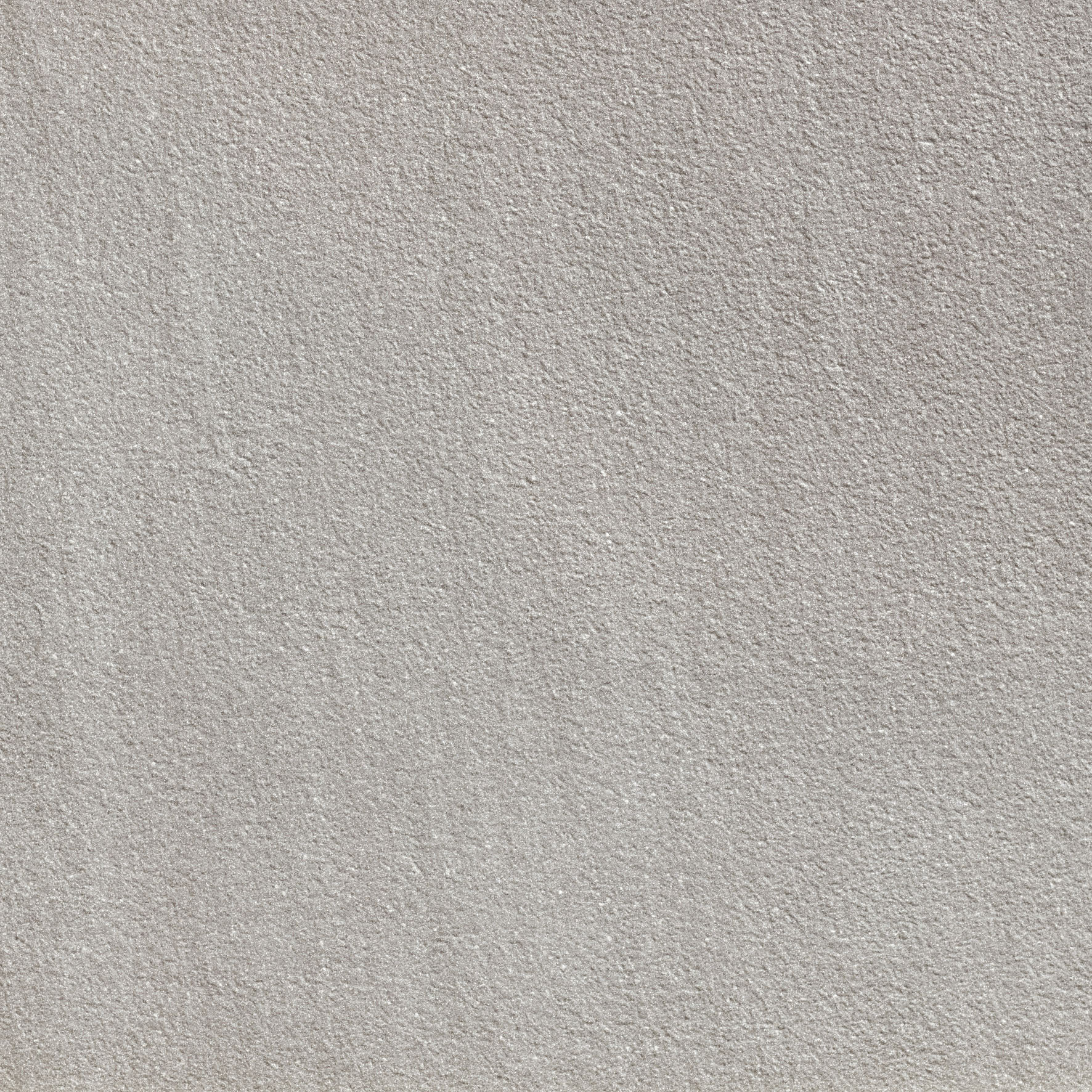

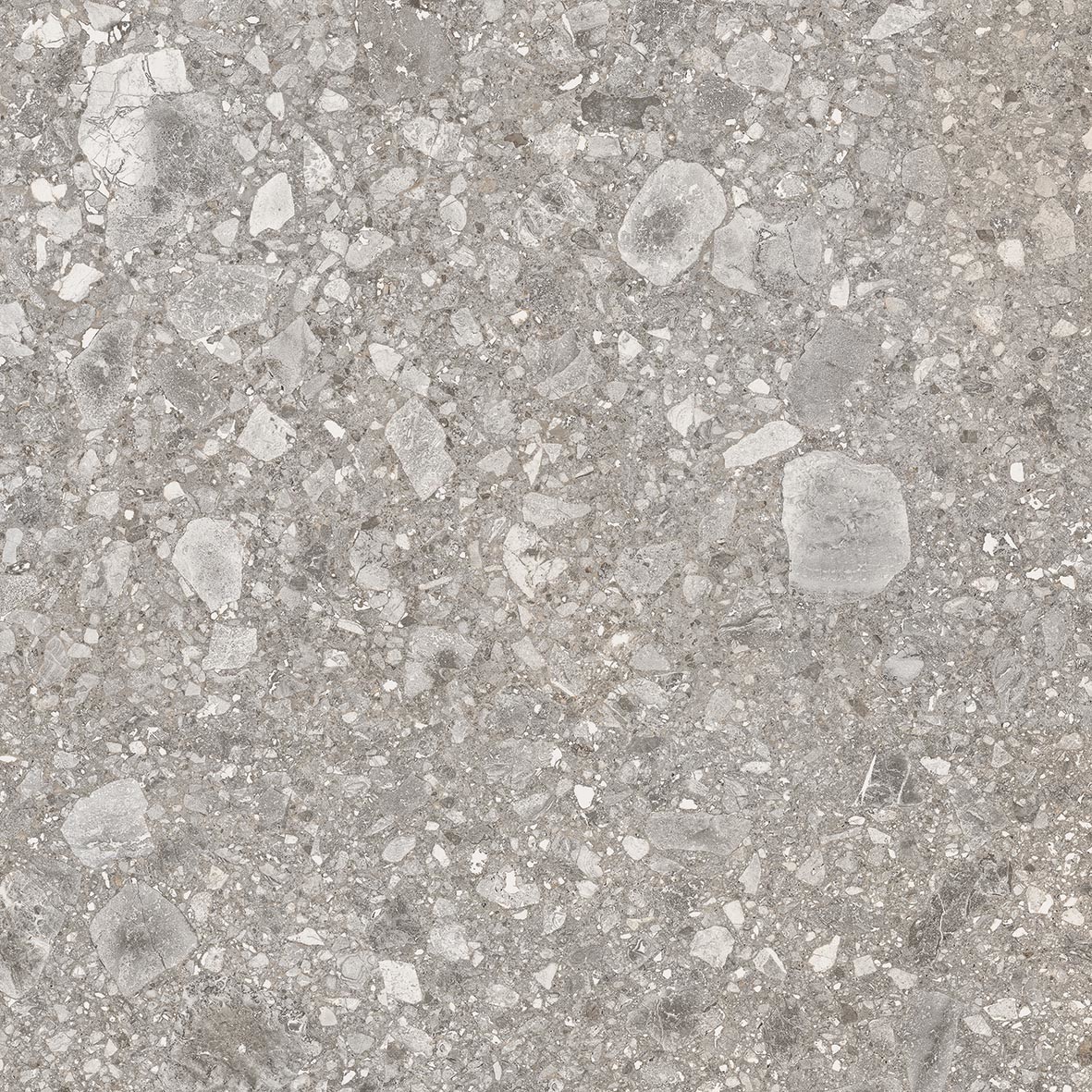

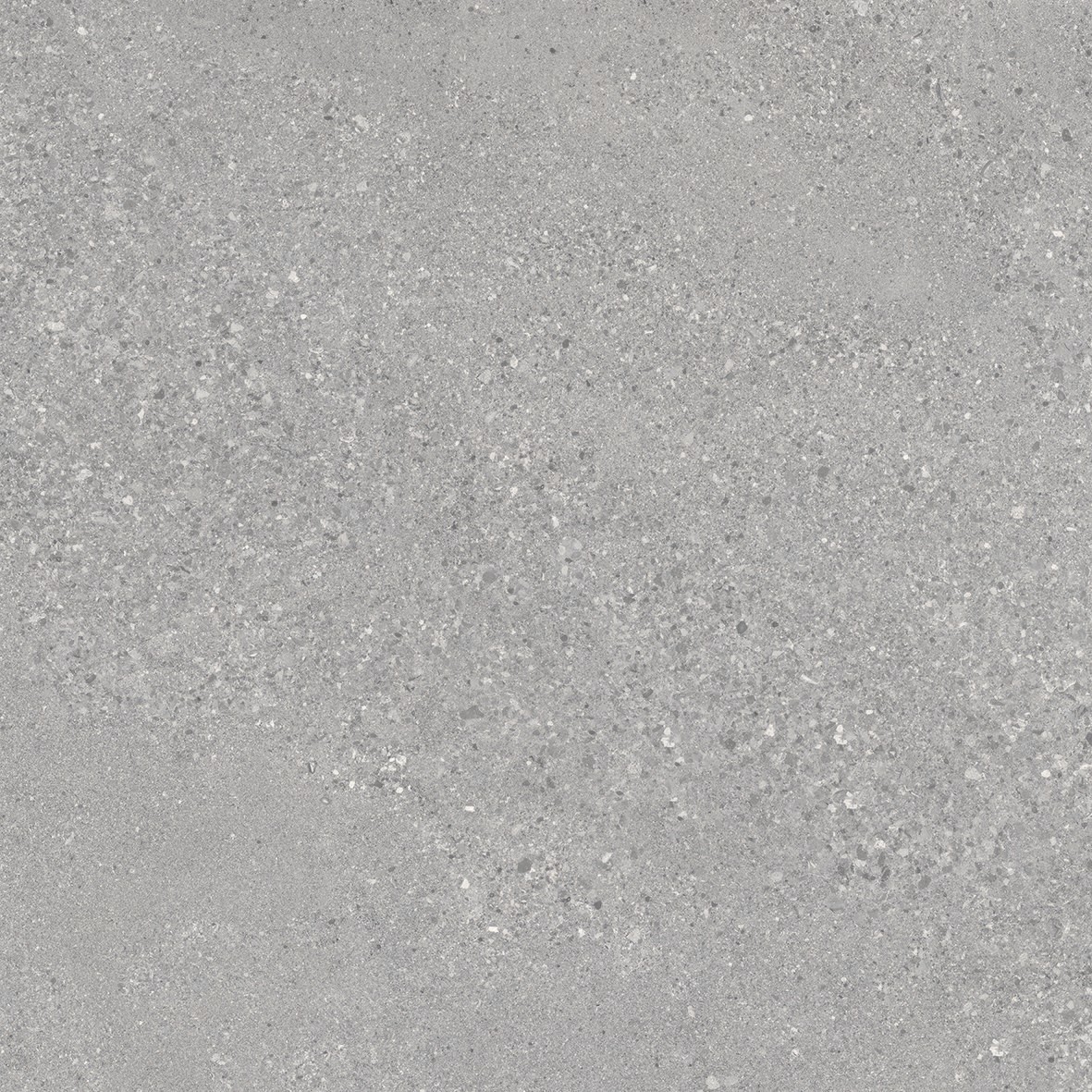

ABL Sockel System® Colour chart

graniitti_05

graniitti_06

graniitti_08

kivi_01

kivi_02

kivi_05

kivi_07

kivi_10

kivi_11

terrazzo_04

terrazzo_05

terrazzo_07

terrazzo_08

terrazzo_09

puu_01

| 30x60cm | 60x60cm | 40x80cm | 60x90cm | 45x90cm | 60x120cm | |

| betoni_03 | x | x | ||||

| betoni_05 | x | x | ||||

| betoni_07 | x | x | ||||

| graniitti_05 | x | x | x | |||

| graniitti_06 | x | x | x | |||

| graniitti_08 | x | x | x | |||

| kivi_01 | x | x | x | |||

| kivi_02 | x | x | x | |||

| kivi_05 | x | x | x | |||

| kivi_07 | x | x | x | |||

| kivi_10 | x | x | x | |||

| kivi_11 | x | x | x | |||

| terrazzo_04 | x | x | ||||

| terrazzo_05 | x | x | x | |||

| terrazzo_07 | x | |||||

| terrazzo_08 | x | |||||

| terrazzo_09 | x | |||||

| puu_01 |

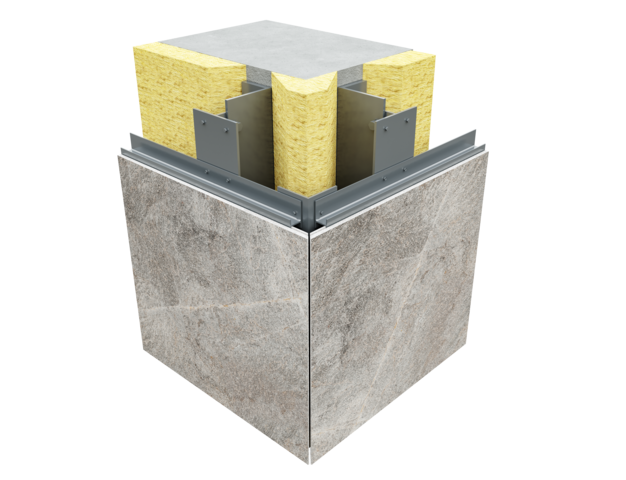

In case of this installation method, horizontal rails are attached directly to the structures, bringing the plinth tiles especially close to the frame. The distance between the wall and the tiles is short: only 40-50mm from the wall to the tile surface. Spacers (5mm) are used for installation and/or the horizontal rail is perforated to allow any water to escape and to ensure sufficient plinth ventilation. The horizontal rail should be perforated at 500mm intervals (hole diameter ø 10mm).

Grooved dry-pressed tiles are attached to the horizontal black anodized aluminium rail by sliding or suspension. The tile joint spacing should be at least 4mm. The tiles are jointed using an elastic sealing compound. To ensure rear ventilation, vertical joints should be left open if the installation extends below the ground level. Apply an at least 1cm wide stripe of installation adhesive to the underside of each tile. Make sure the glue cannot block the rail perforations. The structural designer must check the project-specific fastenings and joints.

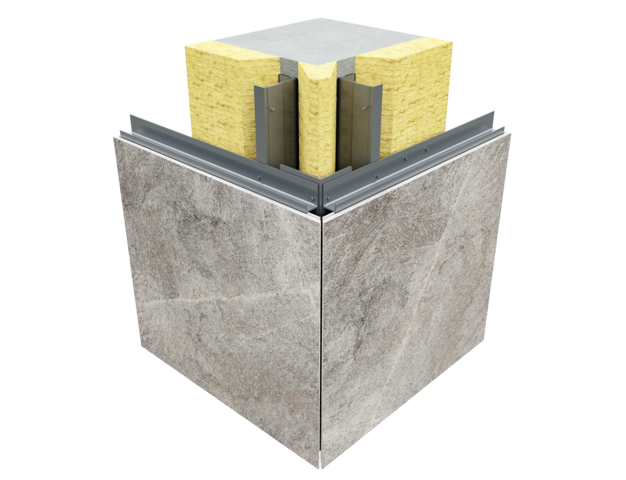

This installation method allows use of thermal insulation in the structure. The frame system is rear-ventilated; the distance between the wall and the tile surface varies between 70-500mm depending on the system. The horizontal rail of the frame is perforated to allow any water to escape and to improve plinth ventilation. The horizontal rail should be perforated at 500mm intervals (hole diameter ø 10mm).

Grooved dry-pressed tiles are attached to the horizontal black anodized aluminium rail by sliding or suspension. The tile joint spacing should be at least 4mm. The tiles are jointed using an elastic sealing compound. To ensure rear ventilation, vertical joints should be left open if the installation extends below the ground level. Apply an at least 1cm wide stripe of installation adhesive to the underside of each tile. Make sure the glue cannot block the rail perforations. The structural designer must check the project-specific fastenings and joints.

ABL Sockel System® façade tiles are available mitred. Depending on their positioning, the short or long side of corner tiles to be installed on the façade can be mitred. We supply mitred tiles in all tile sizes and colours.

Related articles